Lead Former Tooling CF-8

Precision Lead Former Tooling for Axial Components

Eliminate Body Stress with Versatile CF-8 Lead Former Tooling

GPD’s CF-8 eliminates component body stress. Versatility is the key word for the CF-8. Simple tooling changes make short or long run production jobs quick and easy.

Capabilities

- Meets exacting military standards

- Extremely low maintenance

- Eliminates component body-to-lead stress

- Forms axial leaded components either vertically or

horizontally

- Repeatability of station settings are controlled to

± .002″ (0.05 mm)

- Form loose or taped axial-leaded components

- Tooling change-over is quick and easy

- Form components with lead diameters between

0.015″ (0.38 mm) and 0.060″ (1.52 mm)

Production Rates

- Tape mounted components up to 25,000 parts

per hour

- Loose fed components up to 4,000 parts

per hour

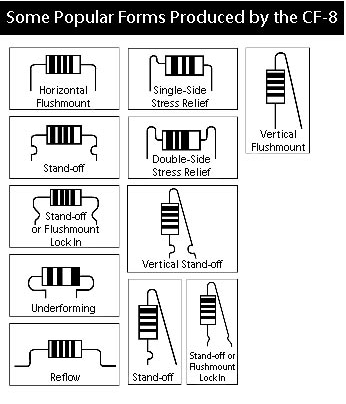

Common Forms

Applications

The CF-8 forms axial leaded components in various form styles:

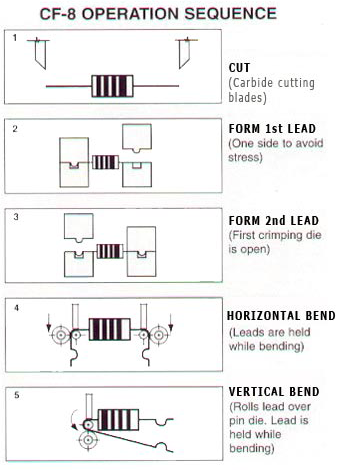

Operational Sequence

A basic illustration of how the CF-8 cuts, forms, and bends axial leaded components.

Key Features

- Control lead protrusion below the pc board with cut-off lock-in tooling to eliminate post solder trimming.

- Lock-in tooling prevents component “float” during wave solder process.

- Stand-off or flushmount lock-in forms for components with lead diameter from .015″ to .060 (0.38 mm to 1.52 mm) and lead material from copper to steel.

- Feed loose or taped components with the same machine. Feed from reels with standard Tape Feeder or in bulk with optional Jacobs Ladder.

- Reduce setup time through repeatable station settings and GPD’s exclusive Calculator Software Package.

- The CF-8 meets the most difficult standards for stress-free/nick-free forming during the forming sequence.

- Standard tooling in stock.

- Station adjustments available in inches or metric.

Accessories

A complete line of accessories ranging from the Calculator Software to an Electronic Counter to the Transport Wheel System is available for use with the CF-8.