Case Study

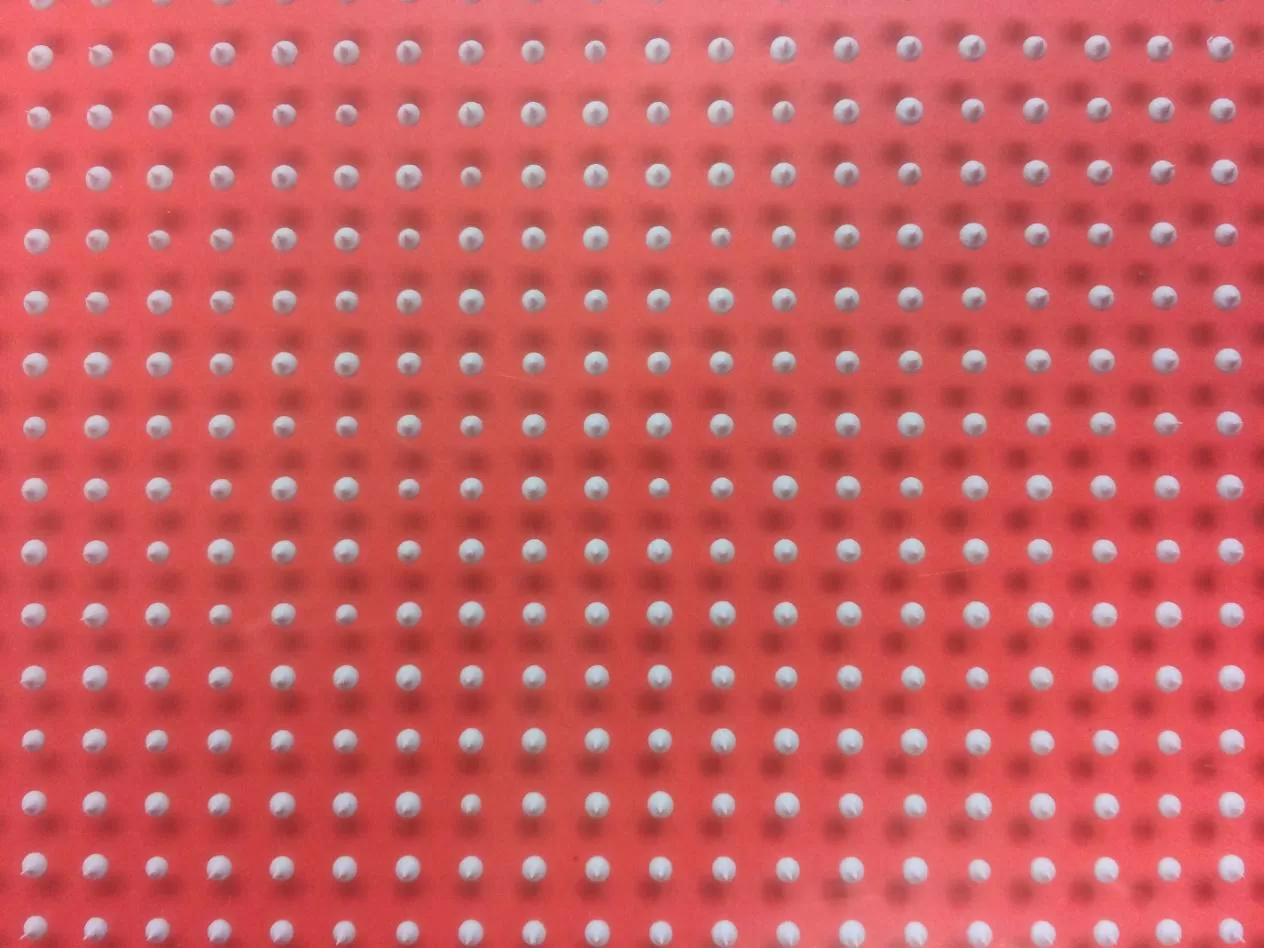

In one of our Consumer Electronics projects, a leader of networking technologies requested to test dispensing performance of a thermally conductive material, Fujipoly Sarcon SPG-50A. This material improves heat dissipation for higher frequency applications and reduces the negative effects of thermal resistance under heat, cold, humid, and thermal shock conditions. The customer’s goal was to dispense a 1mm diameter dot with acceptable speed and consistency.

A tabletop dispensing system, Island Series equipped with a precision auger dispensing pump, 186 16Pitch relieved deep groove Auger was chosen for this highly viscos material. The application specialist chose to use a Luer adapter for 18G S-type nozzles to reduce pressure and to control the material flow rate. The precision auger pump coupled with high pressure fluid control (FPC) keeps the dispensing in an optimal zone. FPC monitors and adjusts the pressure of fluid entering the pump, regardless of fluid reservoir level. Real time control in milliseconds also compensates for variations in fluid volume.

Using the High Pressure FPC configuration, the incoming air is amplified 2x and the system was able to consistently control the fluid flow. A one second delay was added after the pump stopped to assist with surface adhesion.

The information table below displays the key process parameters utilized with the initial testing.

| Pump | Precision Auger with High Pressure FPC |

| Auger | 186 16P Relieved Standard Groove |

| Nozzle | 18G S-Type (0.864mm ID) |

| Material | Fujipoly Sarcon SPG-50A |

| FPC Pressure | 15psi |

| Resulting Syringe Pressure | 60-70psi (peaked at 90psi) |

| Pump Speed | 100 deg/sec |

| Dot Dispense Time | 0.2 sec |

| Pump Reverse | None |

| Dwell for Dot Adhesion | One second |

The High Pressure FPC system coupled with the Precision Auger pump was able to consistently dispense two full syringes without interruption.

The 18G S-Type nozzle was successful in achieving a 1mm dot diameter with the required volume with the throughput required.

| Dispense System | Island Series Tabletop System |

| Dispense Pump: | Precision Auger with Fluid Pressure Control (FPC) |

| Material: | Fujipoly Sarcon SPG-50A |

| Needle Size and Type: | 18G S-Type (0.864mm ID) |

GPD Global offers dispensing system customization and in-house application evaluations with our customers. Call 1.970.245.0408 or email request@gpd-global.com.