Case Study

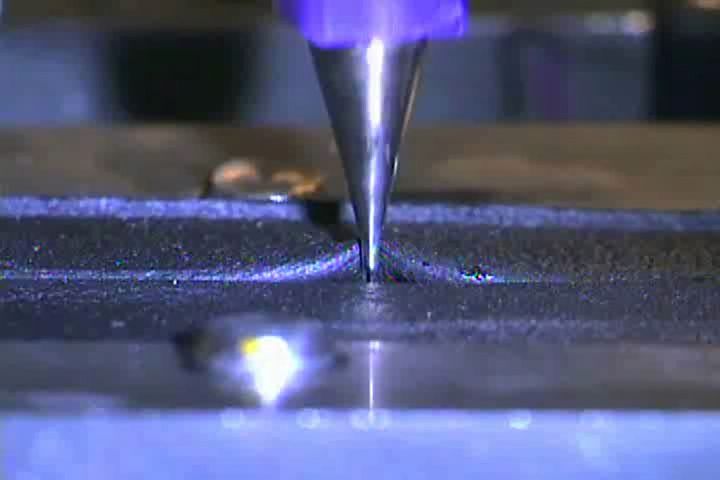

One of our defense customers planned to dispense underfill material for small and large die, using Hysol FP4545FC epoxy encapsulant. This process dissipates stress on solder joints and prevents cracking and fracturing between the bottom of the die and the surface of the substrate.

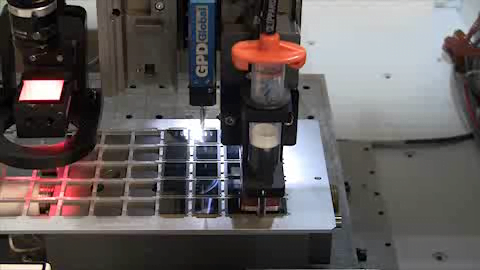

A precision dispensing system, MAX Series equipped with standard features, was recommended. This automated dispensing system is equipped with standard features such as auto vision, contact surface sensor (laser is an alternative), automatic nozzle calibration and nozzle cleaning. Our application specialist recommended the NCM5000 pneumatic jetting pump with the integrated nozzle heater. The customer requested a comparison test with their precision auger pump to determine the most reliable and repeatable result.

The information table below displays the key process parameters utilized with the initial testing.

| Large Die Underfill | Small Die Underfill | |

|---|---|---|

| Pump | NCM5000 | Precision Auger |

| Nozzle | 75µm flat ceramic | 21G S-Type |

| Syringe Pressure | 20PSI | 5PSI |

| Pump Pressure | 45PSI | NA |

| Pump Heater | 45°C | NA |

| Fixture Heater Setpoint | 80°C | 110°C |

| Pump Speed | NA | 100,000 cts/sec (57,000 cts/rev) |

| Open/closed time | 3ms / 10ms (77Hz) | NA |

| Dispense Height | 0.0787in (2mm) | 0.010 in (0.254mm) |

| Dispense Velocity | 0.25 in/sec (6.35mm/sec) | 0.090 in/sec (2.28mm/sec) |

For this evaluation, all parts were run in one batch. The smaller die using the Precision Auger Pump resulted in delays as long as 12 minutes between the first and last unit fill passes. These long delays caused the underfill epoxy to begin gelling and prevented a complete fill.

Our dispense expert informed the customer that processing in groups of 5 would prevent these long delays and the premature gelling of the fluid. More importantly, using the recommended NCM5000 jetting pump reduced the fill pass time as well as the time between passes for capillary flow. A custom heated fixture to hold and heat the parts ensures accurate temperature control during the underfill process.

The NCM5000 jetting pump was recommended for both parts. The wet-out areas were small enough to prevent contact with nearby solder bumps and components. The NCM5000 jetting process significantly improved cycle time versus the precision auger pump.

| Dispense System: | MAX Series System with auto vision, contact surface sensor, automatic nozzle calibration and automatic nozzle cleaning. |

| Dispense Pump: | NCM5000 Jetting Pump |

| Material: | Hysol FP4545FC |

| Nozzle: | 75µm flat ceramic |

GPD Global offers dispensing system customization and in-house application evaluations with our customers. Call 1.970.245.0408 or email request@gpd-global.com.