Case Study

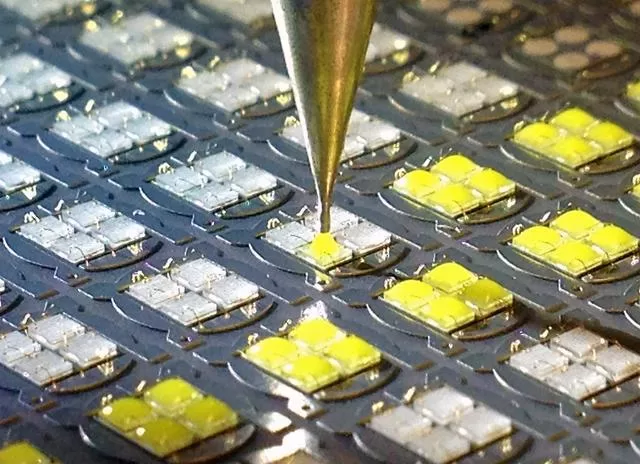

In one of our Consumer Electronics projects, a smart lighting company wished to dispense silicone-based LED encapsulation material for two different product sizes. The larger product had a 9mm circular dam which required silicone dispensing flush with the top of the dam. The smaller product had a 1mm LED die that required only the top to be encapsulated. The material consisted of two parts which were mixed by weight in a 1:1 ratio. A phosphor powder was added totaling 10% of the overall weight. The phosphor required agitation to remain suspended.

A precision dispensing system, MAX Series was utilized for this testing. The MAX automated dispense system was equipped with standard features including automatic vision alignment, contact surface sensor (laser is an alternative), automatic nozzle calibration and nozzle cleaning. The application specialist chose the PCD3H volumetric dispense pump. The PCD3H is a continuously volumetric dispense pump based on the Progressive Cavity principle with capability of dispensing a wide range of fluids, from low viscosity coatings to high viscosity greases.

Proprietary dispense control software aided repeatable dispensing in combination with accurate z-axis positioning for total control of the gantry and valve motion. The optional syringe mixer provided constant fluid agitation, keeping the phosphor powder in suspension for even deposition.

For the larger product, the system was programmed to dispense a single dot in the center of the dam. Dispensing the dot in the center provided the optimal method for material reaching the inner edge of the dam. The dispense height was programmed to be 0.050” (1.27mm) which kept the needle tip away from the exposed wire-bonds and out of the material.

For the smaller product, the system was programmed to dispense a dot while the z-axis was in motion. Due to the small volume of material needed to cover the top of these LEDs, the needle tip started out closer to the LED but moved away as material was dispensed.

| Larger Product | Smaller Product | |

| Needle | 21G S-Type Taper (purple) | 25G S-Type Taper (black) |

| Syringe Air Pressure | 15 PSI | 15 PSI |

| Start Z | 0.050″ (1.27mm) | 0.013″ (0.33mm) |

| End Z | N/A | 0.020″ (0.51mm) |

| Dispense Velocity | N/A | 0.040″/sec (1mm/sec) |

| Pump Forward | 28,000cts | N/A |

| Pump Reverse | 50cts | 325cts |

| Pump Speed | 60,000cts/sec | 1,000cts/sec |

| Pause Before Motion | N/A | 0.35 sec |

| Valve Early Off | N/A | 0.010″ (0.254mm) |

| Dispense Time Per Location | 0.7 sec | 4.5 sec |

The LED encapsulation material dispensed easily, and the phosphor powder stayed in suspension when the syringe mixer was used. The mixer ran continuously at a medium speed to prevent introducing air bubbles into the mixture. The volume of material for each product size met the process requirements.

| Dispense System | MAX Series System with auto vision, contact surface sensor, automatic nozzle calibration and automatic nozzle cleaning. |

| Dispense Pump: | PCD3H Precision Auger Volumetric Progressive Cavity Displacement Pump |

| Syringe Mixer: | Fluid Syringe Mixer/Agitator |

| Material: | Silicone based LED encapsulation Material |

GPD Global offers dispensing system customization and in-house application evaluations with our customers. Call 1.970.245.0408 or email request@gpd-global.com.