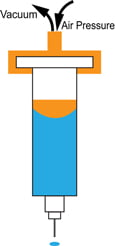

Time pressure is a versatile method of dispensing a wide range of material viscosities. Time pressure dispensing applies pressure pulses to a syringe. These timed pressure pulses are monitored by system software and a pressure controller.

Integrate the Time Pressure Dispense Pumps into fully automated Liquid Dispense Systems or a compact Benchtop equipment.

The amount of pressure used for a timed pressure process is determined by the relationship between the material being dispensed and the application flow rate.

When dispensing is finished, adjustable vacuum prevents syringe material from dripping. Adjustable vacuum prevents air from being pulled into the needle.

Time Pressure Liquid Dispensing prevents material drool when the pump is inactive by maintaining a proper level of vacuum to the syringe. This is especially useful when using low viscosity materials.

Use syringe sizes from 5 cc to 30 cc with the included syringe kit. An optional level detect is available.

Cleanup is simple. All wetted parts are disposable. An operator can change the syringe and needle plus re-calibrate the system within two (2) minutes.

Because material is dispensed directly from the syringe, empty syringes can be discarded. Commonly used Luer-Lok® type needles are also disposable.

Further enhance Time Pressure dispensing results with Advanced Time Pressure FPC (Fluid Pressure Control):

For more FPC advantages, refer to Real Time Process Control with FPC, and watch solder mask dispensed via Time Pressure syringe and Real Time Process Control with FPC.

For specification details, refer to the Time Pressure Retrofit Integration data sheet English / 中文

.