Year in Review: Highlights from 2025

Fluid Dispensing Systems: Driving Precision and Performance

In 2025, GPD Global built on the momentum of the previous year, achieving significant milestones in automation, materials management, and customer collaboration. Drawing from the foundation laid in 2024-where GPD made “remarkable strides in empowering customers to achieve their production goals,” thanks to efficiency gains and material savings across industries—2025 proved to be a year of scaling, specialization, and strategic growth.

Key Achievements in 2025:

- Global partnerships deepened, with expanded service in Asia, reducing customer lead times and enhancing production agility.

- Custom AI dispensing solutions implemented, incorporating real-time sensor feedback and machine learning to optimize fluid control and minimize waste.

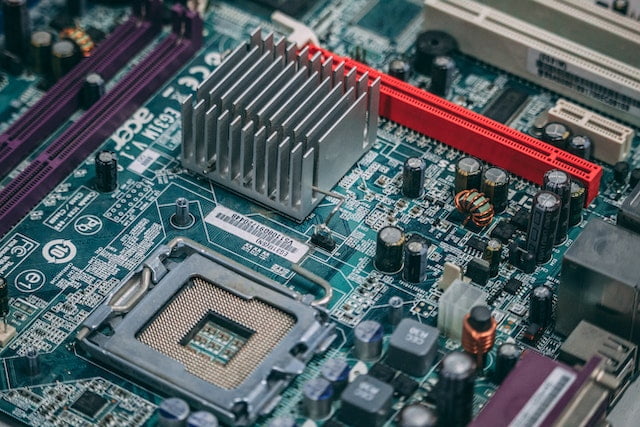

- Diversified into emerging data center computing and next-gen EV power module assembly, adding new verticals to their portfolio.

Real-World Applications This Year

Introduced biocompatible micro-dispensing technologies for implantable and smart point-of-care diagnostic units.

Delivered advanced vacuum potting, and conductive paste deposition under extreme thermal and mechanical conditions.

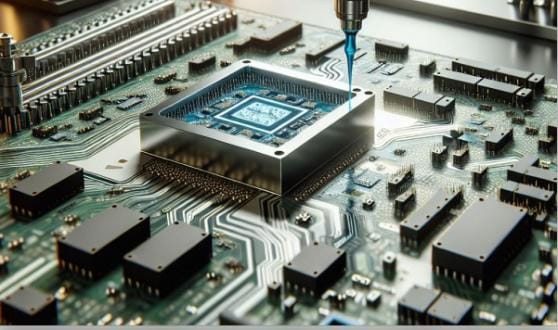

Elevated underfill and thermal interface material (TIM) precision to support high-density substrates and advanced packaging formats.

Powered next-level miniaturization with adhesive and solder paste dispensing, supporting ultra-compact foldables and wearables.

Spotlight: Top Dispensing Applications

Further refinements in micro-droplet accuracy for wearable sensors and microfluidic channel sealing.

Introduction of vacuum-assisted potting for improved coating uniformity in defense products.

Continued evolution of underfill epoxy and staking material dispensing to combat thermal expansion at high compute densities—building on 2024’s successes.

Roll-out of advanced micro-dispensers optimized for flip-chip packaging, hybrid bonding, and wafer-level encapsulation.

Looking Ahead to 2026

GPD Global is setting its sights on the next wave of underfill dispensing innovation. In 2026, the company will accelerate its technology roadmap with several key initiatives, including the launch of a major new dispensing platform:

Introducing UltraMAX™ Fluid Dispensing System — Launching in 2026

The new UltraMAX™ fluid dispensing equipment represents a breakthrough in high‑precision, high‑throughput dispensing for semiconductor packaging applications and PCB assemblies.

Engineered for exceptional accuracy, thermal stability, and intelligent process control, UltraMAX™ is designed to meet the performance demands of next‑generation of fluid dispensing.

This new platform will anchor our 2026 technology portfolio and address the evolving production demands across advanced manufacturing environments.

Alongside the launch of UltraMAX, GPD Global is preparing to:

- Deploy new adaptive pump technologies capable of handling an expanded viscosity spectrum – from traditional epoxies to next‑generation, low‑stress, high‑flow underfill formulations.

- Seamlessly integrate with customers’ inspection platforms and process analytics to enable real‑time verification, zero‑defect manufacturing, and enhanced traceability of all critical dispensing parameters.

- Strengthen its global support ecosystem.

2026 will mark a transformative year for GPD Global, with UltraMAX leading the way into a new era of precision fluid dispensing.

Why Choose GPD Global?

- Deep Expertise: Enabling consistent performance in high-volume, hybrid, and R&D production environments.

- Sustainability Focus: Eco-conscious system designs reduce waste and support cleaner production goals.

- Customer-Driven Innovation: Tailored solutions—from retrofits to fully automated inline systems-backed by responsive support.