Lead Free Solder Paste Dispensing vs. Leaded Solder Paste Dispensing

Compare Solder Paste Dispensing for Leaded vs Lead-free Applications

Solder Paste is used to make electrical connection between a PCB and component. A range of automated fluid dispense systems, coupled with a selection of precision dispense pumps, provides a versatile method of applying solder. Unlike a screen printer that is fixed in pad placement and volume, a dispenser can easily alter dispense location and volume based on adjusted program parameters. Our line of automated dispense systems and pumps are capable of dispensing any pattern including dots, lines, complex shapes, micro volumes for components such as 01005, and pin in paste.

EXAMPLE: The SnPb sphere in Box A accounts for 87% of total box weight. An equivalent-sized sphere of the less dense SAC 305 formulation (Box B) accounts for a lesser percentage of the total weight, 13% to be exact.

Solder Paste Dispensing: Leaded vs. Lead Free

Solder paste is a mixture of solder spheres and flux formulated for dispensing. Paste may be leaded or lead free to suit your application requirements.

There are four main types of solder paste: Flux type, Metal Makeup, Metal Percentage, and Sphere size (type).

When dispensing solder paste, we are primarily interested in metal percentage and sphere size. Metal percentage is the percentage of metal to flux based on weight.

Since leaded paste (SnPb) has a higher density than a common lead free (SAC305) paste, we recommend adjusting metal percentage when changing from leaded to lead free. A percentage of up to 88% metal is common for leaded pastes while a lead free equivalent falls in the range of 78-83%.

Solder Paste Dispensing: Dot Sizing

When using a dispense tip with a larger internal diameter (ID), recommended metal percentage levels may be increased. Selecting a solder paste type (solder sphere diameter) in many ways defines the smallest dot that can be dispensed. Table below shows recommended dot size for several paste types.

| PARTICLE TYPE | MESH SIZE | MICRON SIZE | DOT SIZE (MM) |

|---|---|---|---|

| 3 | -325 +500 | 45-25 | >0.50 |

| 4 | -400 +635 | 38-20 | >0.40 |

| 5 | -500 | 25-15 | >0.25 |

| 6 | -635 | 15-5 | >0.15 |

Solder Paste Dispensing with Auger Pump

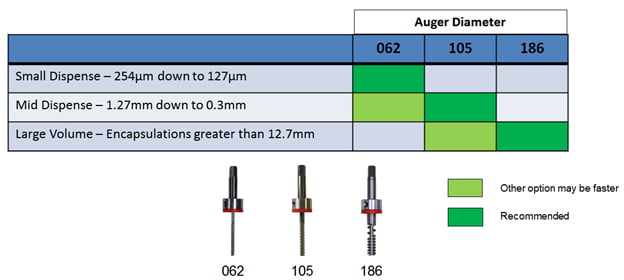

Solder Paste Dispensing is best accomplished with an auger pump. Precision Auger pump handles a wide range of dispense processes with a simple configuration change. Auger/cartridge assembly is available in three different diameters. It accommodates solder spheres without damage.

A correctly selected nozzle manages pressure and ensures a consistent, accurate dispense process. Our standard Precision Dispense tips for Precision Auger pump improve wetting in sizes down to 100 µm. They are available in either steel or ceramic.

Solder Paste Dispensing with Real Time Process Control

Couple our Precision Auger Pump with Real Time Process Control System (FPC) for improved dispensing results over full range of syringe fluid level. Real Time Process Control ensures a constant supply of fluid to pump regardless of reservoir size or fluid level. FPC monitors pressure of fluid entering dispense pump and makes adjustments to reservoir feed pressure, resulting in a consistent feed to pump.

Additionally, we offer a retrofit kit for retrofitting a Precision Auger Pump into your platform. Retrofit kits come complete with a controller and the necessary interface cables and mounting.

Solder Paste Dispensing and Automated Fluid Dispense Systems

GPD Global’s fully automated fluid dispense systems – MAX and DS Series – have features necessary for a successful dispense process such as fiducial alignment, surface sensing on multiple levels, and ability to program complex patterns that may be recalled as needed. Compatibility with our full range of dispense pumps and the ability to use up to three pumps in a single process makes our systems exceptionally versatile.

More solder paste dispensing information: