Case Study

A global aerospace and defense leader requested a capability test of small volume solder paste dispensing on FR4 circuit boards.

A precision dispensing system, MAX Series was utilized for this testing. The MAX automated dispense system was equipped with standard features including automatic vision alignment, contact surface sensor (laser is an alternative), automatic nozzle calibration and nozzle cleaning. The application specialist recommended the Precision Auger dispensing pump. The .062 diameter / 32Pitch auger along with 31G Precision needle (0.133mm ID) was chosen for this project.

The information table below displays the key process parameters utilized for capability testing.

| Pump | Precision Auger |

| Auger | .062 Diameter / 32Pitch auger |

| Needle | 31G Precision (0.133mm ID), 6mm long |

| Syringe Pressure | 10 psi |

| Dispense Height (Z) | 0.0762mm |

| Settle/Snap-off Z | 0.762mm |

| Dispense Velocity | 7.62mm/sec |

| Pump Speed | 10,000 cts/sec |

| Snap-off Velocity | 1 in/sec |

| Pump Reverse | 750 steps |

| Early Valve Off | 0.178mm |

| Pre Snap-off Delay | 0.050 sec |

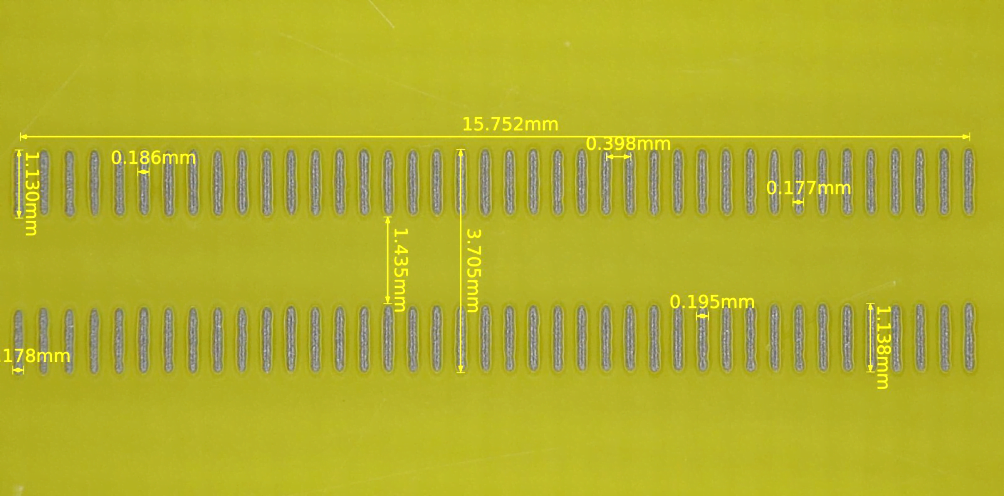

As shown in the example below, the results were consistent and achieved the desired cycle time.

| Dispense System | MAX Series System with auto vision, contact surface sensor, automatic nozzle calibration and automatic nozzle cleaning. |

| Dispense Pump: | Precision Auger |

| Material: | Indium 12.8HF T6 Solder Paste |

| Needle Size and Type: | 31G Precision Needle (0.133mm ID), 6mm long |

GPD Global offers dispensing system customization and in-house application evaluations with our customers. Call 1.970.245.0408 or email request@gpd-global.com.