| Application | Pumps / Accessories |

| Paste, Glue, Adhesive. | |

| High speed, low viscosity. | |

| No drip, volumetric repeatability. | |

| Real time process control. |

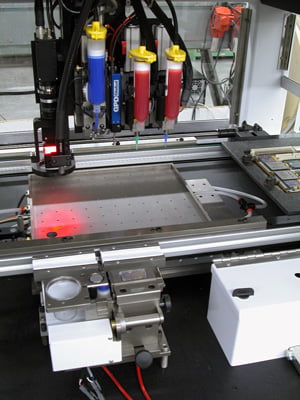

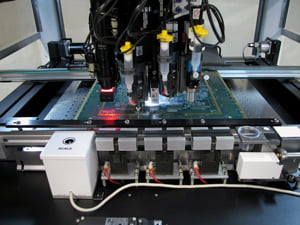

Our DS Series automated dispensing systems are robust, large format platforms that handle all types of applications with ease. Ideal for dispense applications utilizing adhesive, solder paste, conductive adhesive, potting compounds, and more.

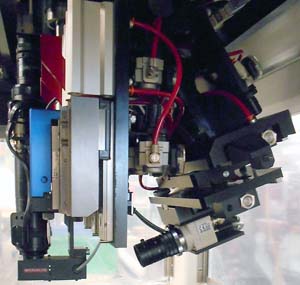

Provides the utmost in versatility and capability. It handles up to 3 different dispense pumps. This system toggles between each pump in a single program. DS Series systems are compatible with all GPD Global dispense pumps.

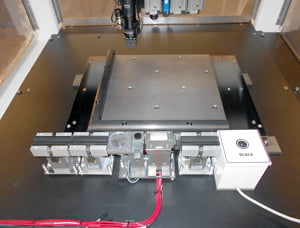

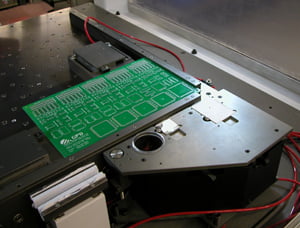

A DS Series highlight – its large work area, up to 24″ x 24″ (610 mm x 610 mm), the largest standard platform in the industry. Available as standalone or inline, it can be configured to meet your production needs. Standalone systems are configured with a flat worktable and board crowders that hold product to a registered location. For additional support, work table may have vacuum ports or support custom fixturing. Inline configurations include an Entrance, Work Area, and Exit zone. Each zone is configured with a board stop and product present sensors to track product through the system.

For applications requiring heat, the work table on standalone systems may be heated to 200° C. All three zones of a conveyor inline configuration may be heated via convection or conduction. Pumps may also have heat applied for fluid that perform better under an elevated temperature environment. Convection heating is very versatile and not subject to bottom-side board geometry.

DS Series dispense system construction is based on a welded steel frame that has been carefully manufactured for high accuracy manufacturing. During assembly the system is subjected to a number of alignments and setups to ensure highest level of precision. After manufacturing, systems undergo contour mapping process for final touches on positioning capability.

All DS-Series models are well suited for multi-functional applications combining dispensing with light assembly / pick & place applications.

A host of options are available to expand the capability of your dispense system.

The DS Series automated dispensing system has largest standard work area in the industry of 24″ x 24″ (610 mm x 610 mm). Available in either an inline or stand-alone configuration.

| Application | Pumps / Accessories |

| Paste, Glue, Adhesive. | |

| High speed, low viscosity. | |

| No drip, volumetric repeatability. | |

| Real time process control. |