S-Type Fluid Control Nozzles, also known as S-Type Fluid Dispene Tips, are engineered to optimize fluid flow and improve dispensing performance across a wide range of applications. These tips are ideal for high-precision dispensing tasks in electronics manufacturing, PCB assembly, and micro-dispensing environments.

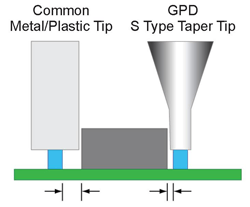

Innovative Tapered Design for Superior Dispensing

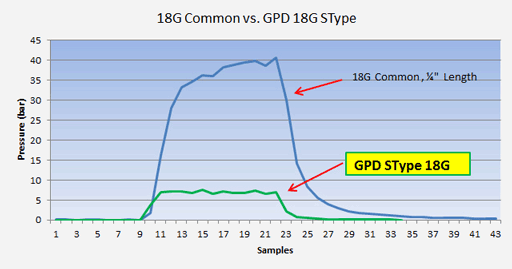

The unique conical taper of S-Type dispensing tips significantly reduces back pressure along the fluid path. This design minimizes clogging, especially in high-viscosity materials, by eliminating the pressure buildup commonly seen in long, narrow tubes. The result is smoother, more consistent dispensing with improved repeatability and reduced downtime.

Benefits of S-Type Dispensing Tips

GPD Global offers a wide range of S-Type dispensing tip sizes, with inner diameters (I.D.) ranging from 0.002″ to 0.049″ and corresponding outer diameters (O.D.) optimized for minimal footprint. These tips are available in high-performance materials such as:

Each tip is color-coded by gauge for easy identification and selection.

Outer Diameter Comparison

Compared to standard medical tubing, S-Type tips offer a significantly reduced outer diameter for the same gauge, allowing for more precise placement and reduced interference in compact assemblies.

| GAUGE | MEDICAL TUBING O.D. (mm / inch) | GPD TYPE O.D. (mm / inch) |

|---|---|---|

| 17 | 1.473 / 0.058 | 1.245 / 0.049 |

| 18 | 1.270 / 0.050 | 1.067 / 0.042 |

| 19 | 1.067 / 0.042 | 0.889 / 0.035 |

| 20 | 0.909 / 0.036 | 0.813 / 0.032 |

| 21 | 0.812 / 0.032 | 0.635 / 0.025 |

| 22 | 0.711 / 0.028 | 0.508 / 0.020 |

| 23 | 0.642 / 0.025 | 0.406 / 0.016 |

| 25 | 0.516 / 0.020 | 0.305 / 0.012 |

GPD S Type Taper Fluid Control Nozzles & Kit Specifications by Part Number

| I.D. (mm / inch) | O.D. (mm / inch) | GAUGE | METAL | COLOR | PART NO. |

|---|---|---|---|---|---|

| 1.041 / 0.041 | 1.245 / 0.049 | 17 | PB with EN* | Pink | 10/4784 |

| 0.864 / 0.034 | 1.067 / 0.042 | 18 | Tan | 10/4785 | |

| 0.686 / 0.027 | 0.889 / 0.035 | 19 | Green | 10/4786 | |

| 0.609 / 0.024 | 0.813 / 0.032 | 20 | Light Blue | 10/4787 | |

| 0.564 / 0.022 | 0.635 / 0.025 | 21 | Purple | 10/4788 | |

| 0.437 / 0.017 | 0.508 / 0.020 | 22 | White | 10/4789 | |

| 0.335 / 0.013 | 0.406 / 0.016 | 23 | Red | 10/4790 | |

| 0.233 / 0.009 | 0.305 / 0.012 | 25 | Black | 10/4791 | |

| Standard Nozzle Sample Kit | 17-25 | see above | 10/4783 | ||

| 0.152 / 0.006 | 0.254 / 0.010 | 30 | NS with EN† | Dark Blue | 10/4792 |

| 0.102 / 0.004 | 0.200 / 0.008 | 32 | Orange | 10/4793 | |

| 0.051 / 0.002 | 0.150 / 0.006 | — | NS‡ | Yellow | 10/4794 |

| µm Nozzle Sample Kit with .002, .004, .006 I.D. | see above | see above | 22110499 | ||

| KEY: * PB with EN = Phosphor Bronze with Electroless Nickle † NS with EN = Nickle Silver with Electroless Nickle ‡ NS = Nickle Silver with no plating Contact GPD Global regarding other standard metals. | |||||

For detailed specifications, part numbers, or to request a quote, contact our technical support team for personalized assistance.

To maximize the performance of your S-Type fluid control nozzles, consider these professional dispensing tips: