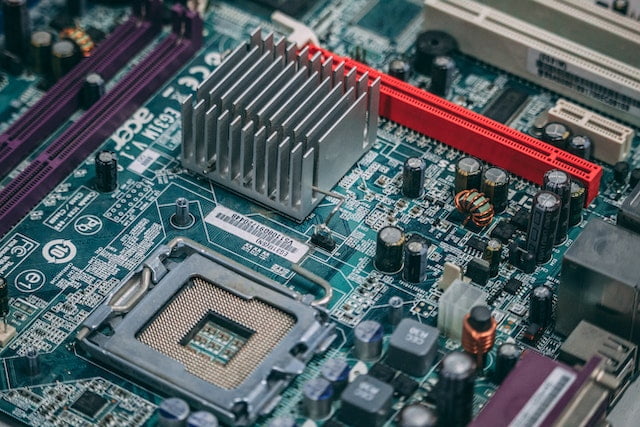

In the traditional sense, semiconductor packaging refers to a “housing” or “case” that contains one or more integrated circuits or discrete semiconductor devices. These can be made from plastic, ceramic, metal, or glass. Fluid dispensing systems with a selection of pumps/valves provide a critical step in ensuring semiconductor packages are protected from radio frequency emission, electrostatic discharge, mechanical damage, and heat. Fluid dispensing accuracy, speed and reliability are a necessity for applications requiring underfill, heat dissipation and micro-dispensing of solder-paste, conductive epoxies and encapsulants for multi-level packages and MEMS devices.

We have a long history of providing fluid dispense equipment for the semiconductor assembly and test industries since 1995. Our superior applications support helps companies in these industries choose the right fluid dispense equipment necessary to protect packaging when applications require underfill, heat dissipation for advanced ICs. Precision solutions for micro-dispensing of solder-paste, conductive epoxies and encapsulants for multi-level packages and MEMS devices are readily available.

View more information about specific applications such as potting, component underfill, module encapsulation, staking, micro-dispensing, micro-volume solder-paste dispensing, component staking, COB (wire bonded device) encapsulation, TIMs for heat dissipation, solder-paste, and conductive epoxies