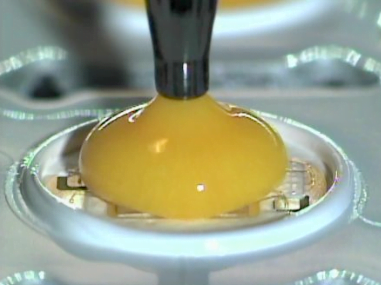

LED Manufacturing Dispense Pump

GPD Global’s PCD4H LED Manufacturing Dispense Pump Improves Yields for LED Manufacturers

When dispensing a phosphor filled encapsulant, the PCD4H is configured with a syringe mixer to keep the encapsulant homogeneous over its entire pot life. The adjustable speed of the syringe mixer and a rotating element designed to create turbulence ensures encapsulant homogeneity. Repeatability of volumetric dispense is not affected by varying levels of fluid in the syringe or the change in viscosity over the pot life. Additionally, repeated calibration is not required during the pot life to maintain volumetric consistency. PCD4H is a continuously volumetric dispense pump that is not limited to a certain volume and does not require trial-and-error setup to reach a desired volume. One pump is able to dispense a full range of device sizes without any changeover.

Air-free syringe changeover is made possible with ergonomically placed bleed ports, eliminating the need to purge to remove trapped air bubbles. Additionally, using GPD S Type Taper Tips will improve dispense performance by minimizing fluid pressure at the dispense tip and enhancing fluid flow. No drip or drool is present after the dispense process. The PCD4H has high flow rates and outstanding repeatability to improve yields for LED manufacturers.

PCD4 and PCD4H pumps are available on GPD Global Max, DS and Island Series robots. For more information or to inquire about PCD integration into existing robots, visit www.gpd-global.com.