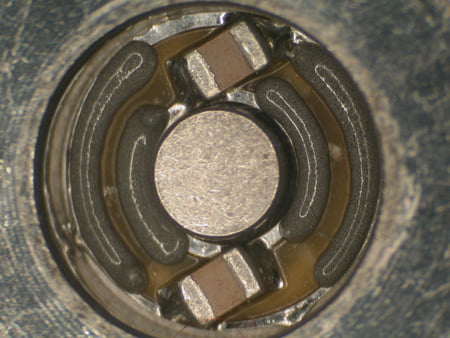

The Precision Auger pump uses a servo motor to control pump rotation. An encoder monitors auger position. Precise motion achieved by the encoder results in uniform dispensing with much greater accuracy than is available from a non-encoded pump.

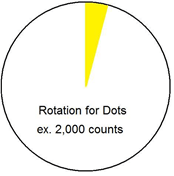

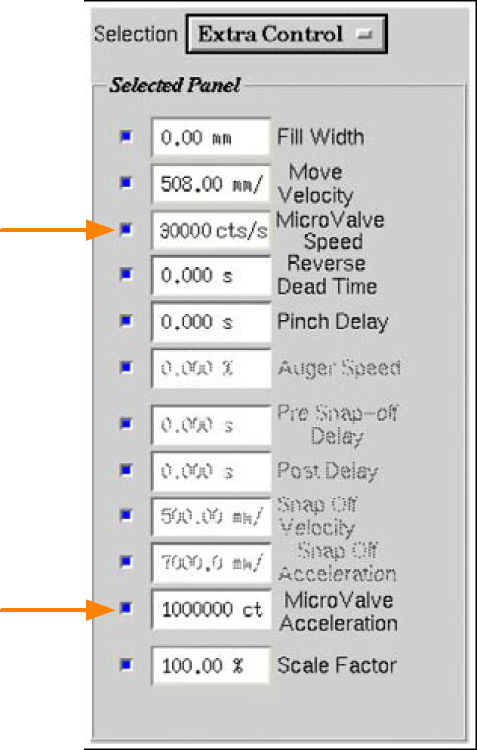

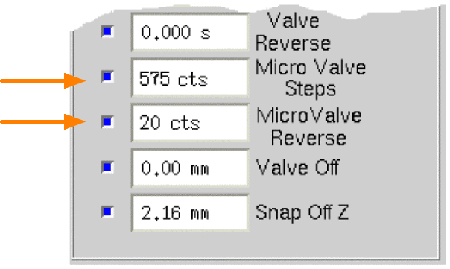

When programming dots or singular dispenses, the operator may set the number of counts per dispense.

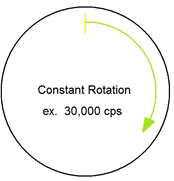

When programming lines or area fills, the operator may set the dispense rate of the pump. This determines the constant speed of the pump during operation.

In both cases, the acceleration, deceleration, and reverse motion parameters can be set. These parameters can be saved to a specific pattern (shape), placed in programs and used as often as you like. Being able to save dispense parameters with a specific pattern – not just to a single aspect of dispense – makes programming large varieties of product using similar components very easy.