Standard features on the SimpleCoat and SimpleCoat TR models provide you with low cost conformal coating system. More capabilities at lower cost.

The SimpleCoat drive system consists of a 3 axis robot driven by reliable stepper motors. With positioning repeatability of 50 µm, your coating results will be consistent from first-to-last product.

Maximum speed for the drive system is 300 mm per second to minimize time between long moves.

The powerful and intuitive user interface for the SimpleCoat conformal coating machine is installed on a user-supplied laptop. Features include programming from .JPG as well as traditional teach methods.

SimpleCoat uses a Pin Chain conveyor for product transport. This is a robust type of conveyor and holds up to solvents and chemicals used in conformal coating. Additionally, heavy pallets can be easily transported on the pin-chain conveyor. When a product enters the work area, it is positioned by a set of product stops, one on each rail.

Adjusting the system for the next product is quick and easy. Conveyor width is adjusted manually by loosening two locks and then sliding the rear conveyor rail into position. Board stops and sensors do not require adjustment.

One spray valve and one needle valve are standard with machine. Optional Volumetric pump is available.

| VALVE | DISPENSE FEATURES | |

|---|---|---|

| Spray Valve | Standard | Coats large areas with a 10-12 mm wide conical spray pattern. |

| Needle Valve | Standard | • Beads and Dots • Solder Mask • Damming • Luer Tip compatible |

| Volumetric Pump | Optional | • True volumetric • Adjustable flow rate • Masking • Damming • Luer Tip compatible |

Stainless steel cups are positioned at the rear of the work area. Two cups are filled with solvent to keep dispensing tips clean while not in use. The other two cups are for purging before a process begins. Each cup holds150 ml (5 ounces) and is easily removed for cleaning.

Conformal coating generates toxic fumes that need to be removed from the working environment. Solvents used in conformal coating are heavier than air and settle in the bottom of the work area. An exhaust port with filter is located below our stainless steel work area cover. The filter captures any large particulates, which allows toxic fumes to be pulled through the exhaust port at the rear of the system. The fume filter is easily replaced by removing four fasteners. As a mandatory safety precaution, the exhaust port includes a flow sensor. If flow drops below a set point, the sensor prevents the coating system from operating.

Reservoirs, mounted outside the system, are standard. These reservoirs are easily accessible for refilling and cleaning. Each reservoir has a pressure regulator for process optimization.

Large reservoirs, as well as level detects, are available as an option.

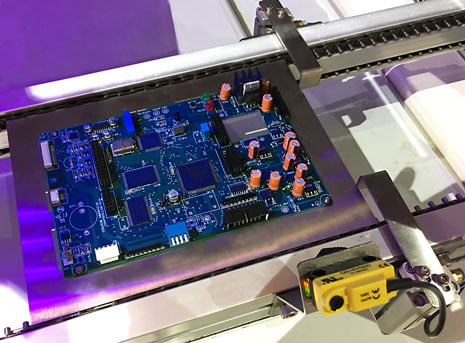

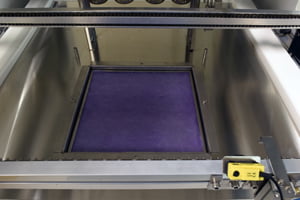

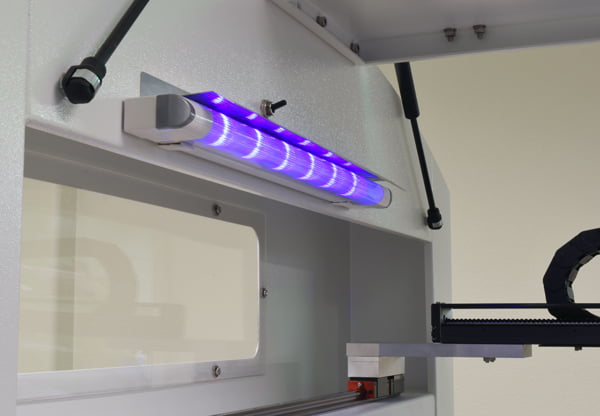

Many conformal coatings fluoresce when exposed to a blacklight. This fluorescence helps determine if a product is fully coated. The SimpleCoat platform includes an internal black light; this enables an operator to assess if coating is being properly applied from outside the system.

Adjustments are kept to a minimum with SimpleCoat. The front panel has an adjustment for spray pressure to control cone width and pattern. A lock is also provided to prevent operators from opening the front shield during processing, thus preventing fumes from escaping the dispense chamber while also preventing operators from exposure to a moving gantry.