In electronics manufacturing, “underfill” refers to a material that is applied to fill the gap between a semiconductor device, such as flip-chip assemblies, Ball Grid Arrays (BGA), or Chip Scale Packages (CSP), and the substrate, such as a PCB or flex circuit. It is also important in 3D ICs and advanced packaging technologies that involve stacking multiple chips or integrating multiple functions into a single package. Underfill materials are essential in modern electronics manufacturing and are used extensively to enhance the reliability, performance, and longevity of electronic assemblies. These materials improve mechanical strength by enhancing the mechanical bond between the chip and substrate, reducing the risk of solder joint failure due to mechanical stress.

In applications where it is important for the assembly to withstand thermal cycling, underfills improve thermal cycling performance by reducing the risk of failures due to thermal expansion and contraction. Another key benefit of underfills is their ability to provide a protective barrier against moisture, contaminants, and other environmental factors. Underfills can be categorized into four different types: capillary flow and no-flow underfills, as well as molded and wafer-level underfills. This article will focus on capillary flow and no-flow underfills in dispensing applications.

Read the full article about Underfill Materials Dispensing in Electronics

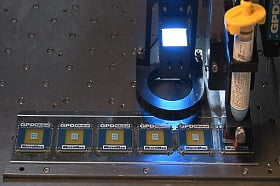

Learn more about GPD’s underfill materials precision dispensing equipment.

Please fill in the form to contact us about Dispensing articles.