6. Calibrating needle

Standard calibration sequence for needle valve.

Before you begin

Equipment required:

- Calibration plate

- Needle valve mounted in the head position to be calibrated

Procedure

- If the system and laptop are not already connected

and if the robot is not already homed:

- From the main button bar, click the Connect button.

- Click OK on the success prompt.

- From the main button bar, click the Home button.

- Set the Run/Maintenance keyed lock on the front control panel to Maintenance.

- Slide the calibration plate into the work area on the

conveyor rails until it is snug against the board stops at 0,0 position.

Figure 5-2. Calibration plate (PN 23116001)

- Calibrate needle:

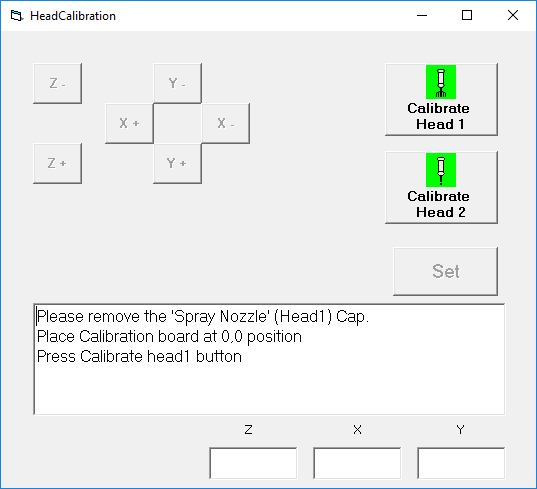

- From the main menu, select The Head Calibration window displays.

-

Click the applicable button: Calibrate Head 1 or Calibrate Head 2. CAUTION

CAUTION

- Using the X and Y jog buttons, center the tip of the needle over the hole in the calibration plate.

- Using the Z axis jog buttons, adjust the tip of needle so it is positioned just above the surface of the calibration plate.

- Click the Set button.

- Click the OK button for each location prompt, and then select YES for the overall offset prompt.

- Use the Z- button to raise the needle upward, away from the calibration plate.

- From the main menu, select

- If a second needle/head position needs to be calibrated, repeat the prior “Calibrate needle” step for that head.

- Remove the calibration plate from the work area and store for future use.

- Close the Head Calibration window.

- Click the Home button.

- Set the Run/Maintenance keyed lock on the front control panel to Run.